Optimized Bottling Plant for Major Mineral Water Client

A major client in mineral water turned to BBM Service to optimize the space in preparation for installing a new bottling plant. It was crucial to find the optimal solution to avoid overlapping the new line with the existing one.

Comprehensive and Integrated Approach

BBM Service’s technical department meticulously studied and developed the new layout of the existing production line. Our approach was comprehensive and integrated, taking on the entire “turnkey” process, starting with a detailed audit and thorough analysis of the client’s requirements. We then explored all possible layout solutions, considering every detail and logistical constraint.

Production Line Modifications and Upgrades

The layout optimization work involved relocating a SIPA blower and adapting the air conveyors. Additionally, we replaced a paper labeler with a used and refurbished BBM labeler equipped with OPP labels. Consequently, the bottle transport conveyors for both incoming and outgoing bottles were also updated. To make room for the new labeler, we relocated the SMI packer, its associated feeding and discharge conveyors, and a pallet wrapper. We provided a rotating platform and pallet conveyors. Furthermore, we revised the management and automation of the conveyors, updating the existing software. The optimized and relocated line is a PET line running at an average speed of 14,000 bottles per hour, and working with half-liter, one-and-a-half-liter, and two-liter formats.

Timelines and Collaboration with the Client

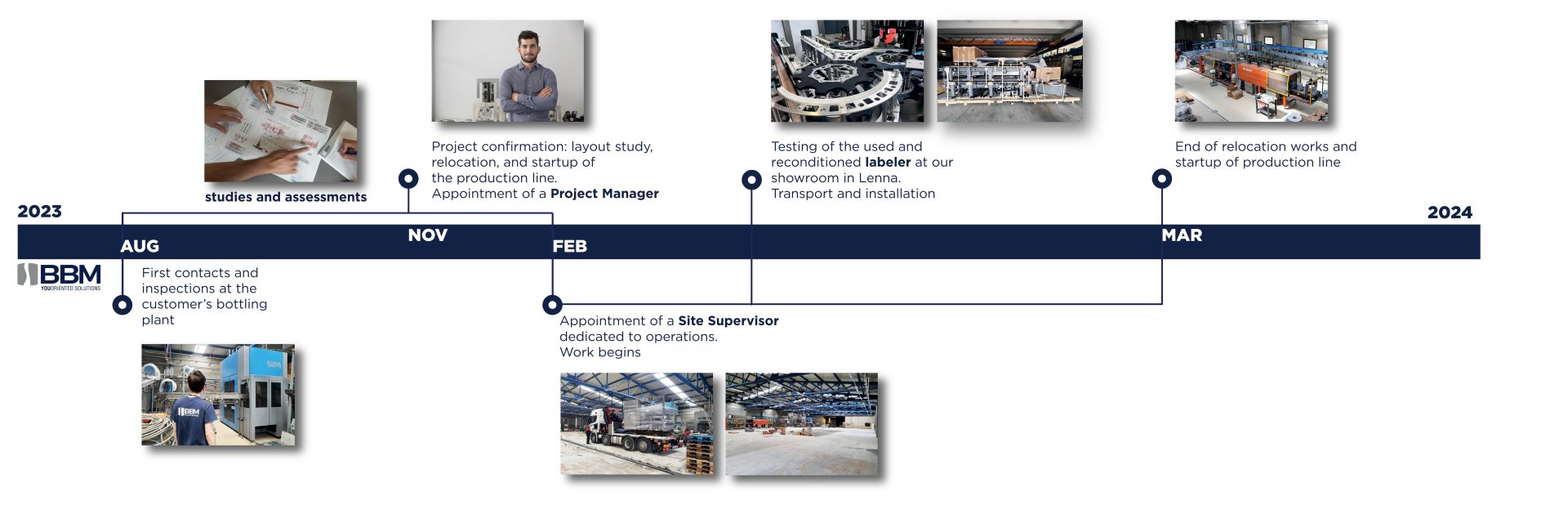

The timeline was tight: contacted in August, we developed several proposals and the order was initiated in mid-November, after three months of contact, studies, and evaluations. We began the relocation work in February, and after a few weeks, we were already in production.

From planning to the selection of materials and equipment, we worked closely with the client, involving them actively in the decision-making process. We assigned an internal project manager, who was the exclusive point of contact for the client, ensuring constant and direct support. This approach allowed us to work more closely with the client, fully understanding their needs and providing tailored solutions. Simultaneously, we appointed a site manager dedicated to the operational part, ensuring that every phase of the relocation and startup was managed with precision and timeliness. Thanks to this role division and collaborative approach, we managed a smooth and seamless process, from the initial study to the full operation of the new production line.

The result is an optimized and efficient production line, ensuring continuous and high-quality production. The facility now operates with two perfectly integrated and complementary bottling lines.

If you are looking for a used and refurbished bottling plant, contact BBM Service. We will be happy to propose the best solution for your needs.