In recent years, the bottling and packaging sector has seen the evolution of numerous key components, including inverters, essential elements in regulating the speed of electric motors according to operational needs. Speed control implies increased productivity and greater accuracy in packaging, as well as improved energy efficiency and reduced operational costs, thanks to power regulation.

However, a significant portion of the inverters currently installed on packaging lines has become obsolete, making a replacement upgrade necessary to avoid unexpected and costly machine downtimes.

Obsolescence of inverters: among the main causes of production downtimes

Many inverters currently in use were introduced to the market over ten years ago. In some cases, they may even be more than 25 years old. Over time, the availability of spare parts for these devices on the market has drastically decreased. If you own one of these inverters, it is crucial to consider replacement, as the shortage of spare parts is expected to worsen. Wear and aging of inverters significantly increase the likelihood of failures. Damage to this component can cause complete machine interruption, as the inverter is essential for communication between the various elements of the system. Obsolescence, wear-related damage, and storage in exposed environments can pose safety issues for operators and lead to the premature degradation of these devices.

How to avoid a potential production halt and reduce economic losses? BBM Service proposes to conduct a machine audit and suggest the best alternative to replace the old inverter. Our team of specialized technicians will ensure the safe provision and installation of new motors and inverters. The intervention, which is of short duration, constitutes a fundamental preventive measure. But what are the main advantages?

The advantages of BBM Service’s inverter replacement

Prevention of unexpected machine downtimes

An obsolete inverter is prone to sudden shutdowns, resulting in operation stoppages. In many situations, restarting the machine temporarily solves the problem, but if this happens frequently, it is likely that the cause is related to a loss of communication between the inverter and the system. By replacing the inverter with a new one, this vulnerability is eliminated.

Improved safety

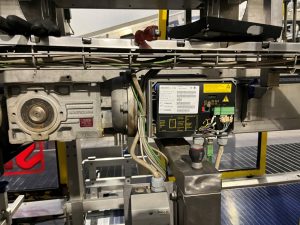

The inverters are installed by BBM in protected areas, shielded from external agents such as water and dust. Unlike old configurations, where the inverter was mounted directly on the motor and exposed to the elements, it is now installed in a dedicated electrical panel, ensuring greater protection and durability. This not only improves wiring management and operational safety but also reduces the risk of failures due to exposure to unfavorable environmental conditions and the risk of electric shock for operators.

Advanced software integration

The upgrade is not just about hardware. The new inverter is integrated with the machine’s control system through advanced software, allowing for more efficient and secure management from the HMI (Human-Machine Interface) panel.

Conclusions

In a market where speed and operational continuity are essential, the obsolescence of inverters poses a real threat to many companies. BBM Service offers a simple and advantageous solution that prevents unexpected failures, improves safety, and optimizes machine performance. Prevention is better than cure: relying on updated technologies ensures an uninterrupted future and greater operational efficiency. If you have any doubts or questions about the obsolescence of your inverters or wish to assess the current condition of your machine, do not hesitate to contact our experts.

For more information on other supplies of electronic components for machinery and bottling and packaging lines, please consult our dedicated page on electronic components.